BEAst Supply 4.0 enables environmental data sharing in building and construction industry

“Contractors that choose Norwegian vendors will know the climate impact of each product and service,” explains Ole Gunnar Honningsøy, strategic advisor at the company Byggtjeneste and a project manager at Byggstand.

Cooperation and data sharing

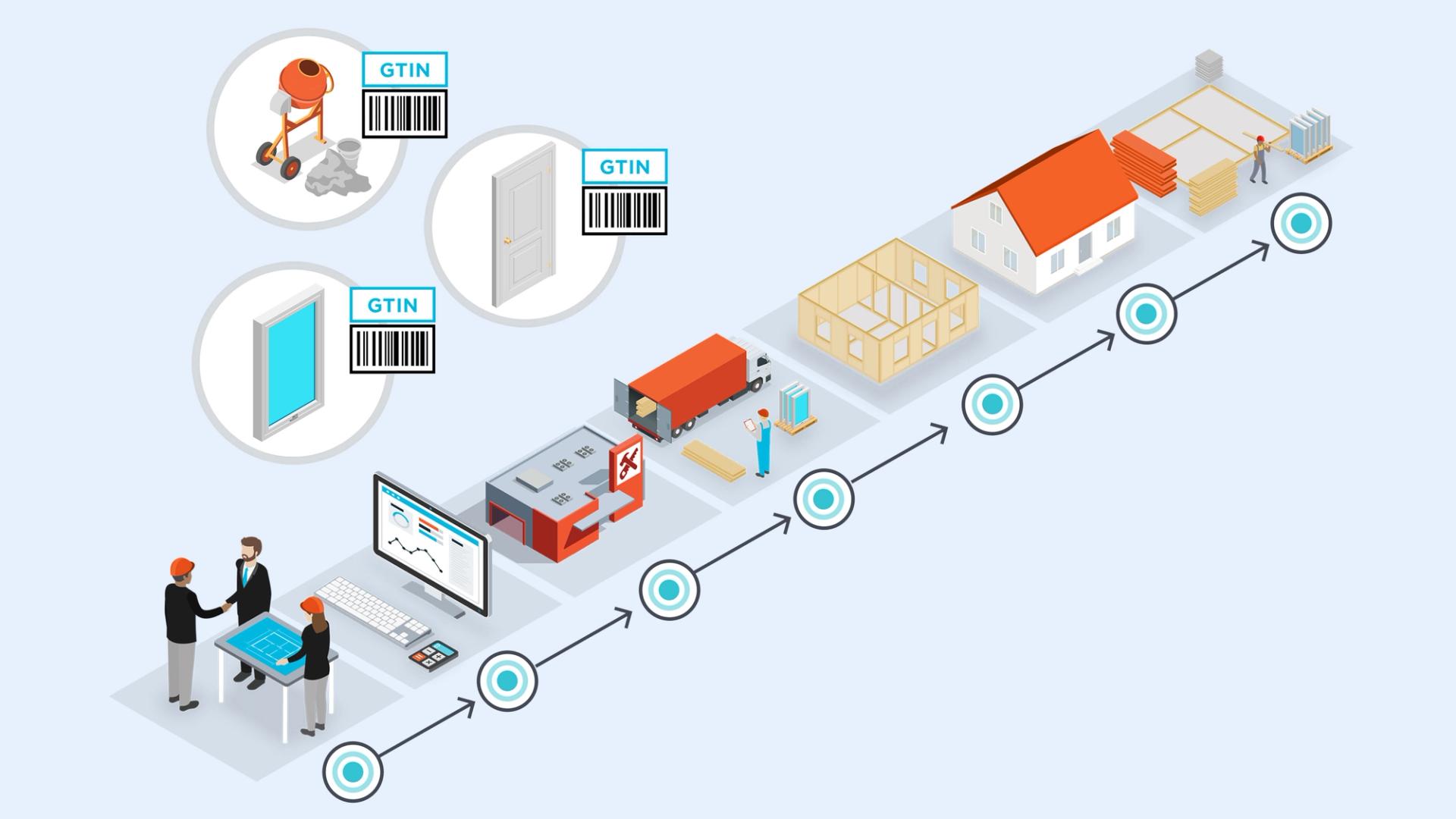

Building and construction is a large, complex industry with fragmented value chains. Since players along the value chain are mutually dependent on each other, cooperation is crucial. But until now, cooperation in the form of data sharing has been the exception rather than the rule.

Norwegian players along the entire building and construction value chain are working to change this through Byggstand, which serves as an information and competency centre for digitalisation.

“Byggstand develops shared digitalisation tools to improve business processes, distribution of goods and documentation among actors in the value chain,” explains Honningsøy.

Digital highway for environmental data sharing for building and construction

Byggstand’s first project is BEAst Supply 4.0, a digital highway for all suppliers that need to share environmental data via established business processes. Free of charge, the solution is easily introduced into existing, standardised IT systems such as ERP software. All data shared is machine-readable.

“Requirements on circularity, climate impact and eco-friendliness have become stricter, while higher transactions costs have made the building process more expensive. In order to meet demands and lower costs, shared digital solutions are needed to improve the packing, labelling and tracking of goods,” says Andre Mamelund, industry coordinator at the Federation of Norwegian Enterprise (Virke) and a project manager at Byggstand.

Climate footprint expressed in recognised values

The concept is to connect all players in the value chain through electronic data interchange (EDI), which allows intercompany communication of business documents in a standard format, replacing paper documents such as invoices and purchase orders.

As a first crucial step, the project has created a place on the electronic EHF invoice to report climate data, allowing suppliers to convey climate information about each one of their products. Documentation is based on the international Environmental Product Declaration (EPD) system, and the products’ climate footprint is expressed in internationally recognised values such as global-warming potential (GWP).

Moreover, the project uses the international standard ISO/IEC 19845:2015 and is part of PEPPOL, the EU standard for electronic invoicing and other business processes.

Enabling cross-border collaboration through alignment with international standards

As the solution is international in scope, vendors both inside and outside Norway will benefit.

“With our platform, Norwegian vendors will be using business processes that align with international standards. This will give them new access to global markets, especially in countries with strict environmental standards,” says Mamelund.

“On the other hand, global vendors that use these standards will gain access to the Norwegian market, provided they can satisfy environmental requirements set by the government,” he adds. “There are opportunities and risks for both sides.”

Another key benefit is increased efficiency in business processes. Thanks to digitalisation, companies can eliminate time-consuming manual work, accelerate and streamline their processes, and, ultimately, lower their costs dramatically.

Moreover, the solution puts the environment high on the industry’s agenda. It empowers companies to choose vendors with a good climate score and, in turn, makes those vendors more competitive in the market. End customers, such as homebuyers, will have a full overview of the climate impact of their purchase.

.png?auto=format&w=1920&q=75)

Revolutionising business processes in the building and construction industry

The solution promises to revolutionise business processes in the industry. Digitalisation is a megatrend throughout society, and companies reluctant to go digital will fall behind the competition.

Ole Gunnar Honningsøy explains:

“We estimate that our digital solution will save NOK 1 200 to 2 000 per transaction. To put this in perspective, a large project may end up with 10 000 invoices. This is a savings of up to NOK 20 million, or EUR 1.75 million.”

The pilot companies in the BEAst Supply 4.0 project are BYGGMA Group, Skanska Norway and Saint-Gobain Distribution Norway. Members of Byggstand cover a range of industry branches, from building materials, electrical and plumbing to home manufacturers, GS1 barcoding and building contractors.